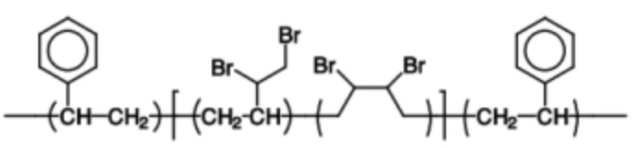

Bromianted SBS(Br-SBS)

Chemical Name: Brominated butadiene/styrene block copolymer/ Brominated SBS

Alternative Name: Brominated styrene butadiene styrene block copolymer, Br-SBS

Equivalent Grade: Great Lakes Emerald Innovation 3000 or ICL FR-122P

CAS NO.: 1195978-93-8

Molecular Weight: Oligomer

Technical Index:

Appearance:White or off-white powder

Bromine content:≥65.00%

Volatile Matter:≤0.3%

pH:5.5~7.5

5% Weight loss(TGA): ≥256℃

Application:

Br-SBS is s a highly effective, new type of polymeric and environmentally friendly and sustainable brominated polymeric flame retardant offering a variety of enhanced performance properties. This innovative flame retardant is an excellent replacement for Hexabromocyclododecane (HBCD) in exterior insulation materials like expanded polystyrene (EPS) and extruded polystyrene (XPS) foam products.

Advantages of Br-SBS replacing HBCD in EPS and XPS as exterior wall insulation materials:

The comprehensive prohibition of HBCD both domestically and internationally has made it a new hot topic for researchers to search for alternatives to HBCD and put them into production. It has been verified that brominated SBS can not only be used as a broad-spectrum flame retardant, but also a perfect substitute for HBCD. The various performance requirements of HBCD substitutes can be perfectly matched with brominated SBS. In terms of environment, health, and safety, brominated SBS has low toxicity and is not classified as a persistent organic pollutant (POP) or toxic (PBT) substance; In terms of flame retardant performance, it is similar to HBCD and meets the regulations of flame retardant standards worldwide (such as the European Union, the United States, Canada, etc.); In terms of foam characteristics, it can effectively maintain the physical characteristics of EPS and XPS foam; In terms of production process, meet the requirements for EPS and XPS stability; Economically adaptable in terms of cost, it can achieve industrial production, and its mechanical properties are improved compared to HBCD.

As a high-quality flame retardant specifically designed to reduce the harm of existing flame retardants, brominated SBS has undergone rigorous environmental, health, and safety assessments and testing, and the results show that this flame retardant has extremely low environmental hazards, toxicity to organisms, and bioaccumulation. Compared with HBCD, its unique macromolecular properties prevent brominated SBS from penetrating the cell membrane and entering the organism. Research has shown that products containing brominated SBS have effectively maintained people's expectations for external wall insulation materials in the market, meeting market requirements in density, compressive strength, fire resistance, water absorption performance, flexural strength, thermal stability, and zero VOC emissions. They can be widely used in buildings such as walls, roofs, underground, and cold storage. Nowadays, many companies have commercialized the use of brominated SBS.

Packaging ,storage and shelf life:

Br-SBS is packed in 20kg per PP woven bags, 20bags on pallet. 8MT per 20’FCL

Store in dry, well-ventilated area. Keep container closed. Keep away from heat, sparks and flames. Store away from incompatibles. Follow safe warehousing practices regarding palletizing, banding, shrink-wrapping and /or stacking.

Shelf life: 3 years.